Mar

02

Mar

02

The End of Everything: Looking back on the Clark Foam Legacy 12 Years Later

- March 2, 2017

- 1 Comment(s)

In 2005 Robert Kelly Slater won his seventh ASP World Title,

famously to the ire of runner-up and long-term adversary, Andy Irons. In 2005

Ben Stiller made an unexpected cameo appearance in the Taj Burrow classic Fair Bits!, alongside the likes of

super-talents such as the Malloy brothers and Rob Machado. In 2005 the ever-fickle Mundaka event was cancelled when the

waves, in a less than shocking manner, failed to arrive. On December 5th,

2005, Clark Foam unexpectedly closed its factory doors forever.

It’s been

just over a decade since the surfing industry was thrown for a loop when it’s

largest supplier of surfboard blanks called it quits, leaving thousands of board

builders, industry insiders, and surfers scrambling for emergency solutions.

Speculation over the cause of this sudden closure and what it would mean for

surfing in general flew rampant (with varying degrees of truth and accuracy),

and people were justifiably scared and confused. In the time since, much has

been said and written about this incident, and of course the sport and industry

has recovered, and in fact even grown, as a result.

Yes, by now

almost everything that could be said about this occurrence has been. Our

intention is not to provide you a play-by-play history of the final days of

Clark Foam. Even the most cursory Internet search will provide you with that

information. The fact of the matter is that Clark Foam was both directly and

indirectly a part of many peoples lives and livelihoods, and often time the

true nature of any event lies in those more personal experiences. For the former

employees and distributors of Clark Foam, this is truer than for most. Though

Clark is no longer around, it’s legacy and standard for quality have shaped

what the surfboard industry has become.

– Joey Estrada

|

| Planer with Clark Foam Badge |

what was your job at Clark Foam, and what did that entail?

– Matt Barker, Product Creation Operations Director, Hurley: My contribution to Clark

Foam started February 1981 and lasted thru September 2005. That equals +50% of my life at the time, and

over 50% of Clark Foam’s existence.

My #1 Job at Clark Foam was to

obsess on the current and future business, design, and material performance

needs of our customers (shapers), and serve their evolving needs with innovative

product offerings, quality product & services, through a collaborative

partnership. In other words, the shapers directed our business. I was just the

eyes and ears (and very lucky to have this vital role).

– Tami Mays, Teacher: I worked for Clark Foam in the

middle office accounting department from 1996-2003. I helped with customer

service, order entry, accounts payable, accounts receivable, payroll, and other

misc. office tasks.

– Matt

Stevens: Executive VP and front office grunt! Ha! I was

responsible for delivering a quality product to the manufacturing floor, which

in turn delivered a quality product to our customers. That entailed a little

bit of everything from getting the hands dirty with blanks, to working in some

complex systems and developing repeatable processes. To put it in context, this

was one of the most highly customized manufacturing facilities to be found. I’m not

talking about robotics or cleanroom high technology, but you’d be hard pressed

to find a more finely tuned batch process capable of the same range of

customizable options and quality. My

job, as it turned out, was really just to make sure our customers were

successful. You wouldn’t believe how much energy went into making sure that when

a shaper was ready to shape, they could work efficiently with the right blanks.

That sounds pretty vague, but that was essentially my job.

– Craig Larsen, Technical Sales at Composites One: I worked in

the Front Office at Clark Foam, at first with Dick Morales and Matthew

Barker. At that time the focus was on

working with customers, both local and foreign on orders, rockers, stocking

needs, and credit. Basically inside sales.

After Dick passed away, we

were going through a lot of operational restructuring. Gordon, with the

leadership of Kim Thress, was moving the plant into a “lean” operation. He

restructured the Front Office to also take care of the inventory management,

including the Hawaii and Florida warehouses, production “batch” planning and

figuring out the truck routes. We were also busy working on new, efficient ways

to increase production and accuracy (double checks) of everything we did at

Clark Foam. We also helped deliver trucks. Lots of working on procedures and

processes. Anyone that has worked for

Gordon knows his passion for process manuals.

relationship with Clark Foam and how did you become one of their distributors?

– Brad Nadell, Owner of Foam E-Z: I had a close relationship with the drivers and the

girls in the office. The relationships

developed from years of talking on the phone and in person as our business grew

over time. Becoming a Clark Foam

Supplier spawned from us simply reselling the blanks to local shapers. As time went on and we grew our reach to

different board builders around the world, the numbers of blanks grew too. Resulting in us becoming one of Clark’s top

resellers in the world.

Clark was obviously hugely

influential for the industry, both during its operation and after closed. What,

in your opinion, accounts for this influence that set Clark apart?

– Matt Barker: At Clark

Foam- we always put the shapers (and end users) at the center of our business

decisions. Besides that, Gordon Clark is

the smartest person to ever serve shapers (and surfing). No one “pays attention” more that Gordon

Clark.

– Tami Mays: Gordon’s

niche was unprecedented. His corner on the market came from years of R&D to

perfect his product.

– Matt Stevens: Nobody else could figure out how to do it

better, or with nearly the same level of service. Clark Foam was so far beyond what anyone else

could put out in quality or quantity. It didn’t leave much room for other

disruptive technologies or competition to emerge as a serious player. Beyond

product, the service model was pretty advanced. Just think of this in Foam E-Z

terms…whether you were out on an island looking for a tow-in board or an

established board builder down the street trying to make a customer happy with

a reverse rocker log, you could easily order up a blank with very specific

bells and whistles and have it dropped at your doorstep in a matter of days,

not weeks. For the commodity blanks that needed to always be available in Foam

E-Z’s racks, we borrowed some smart ideas from others to make availability and

replenishment really easy to achieve. I’m

not sure if I answered what made Clark influential as much as what made it so

dominant and in control of their place in this little niche industry.

– Craig Larsen: Clark

Foam was very supportive of the entire market, especially the small builders,

which was a huge influence on the overall market. It used to drive the bigger builders crazy,

but he was extremely supportive to the small builder because he knew from

history that most of the innovation in surfboard design would come from the

smaller shops because it was easier for the smaller builders to react to market

needs.

But the thing that really set Clark Foam apart

in my opinion is the overall efficiency of the operation. That place was a

well-oiled machine, every process thought out and documented. This efficiency

led to a high level of service to the market. Sometimes it meant that we

couldn’t bend for someone who needed a rush order, but with Gordon, the more

efficient we were, the better service customers were receiving. Gordon is

extremely efficiency minded.

you involved with Clark and their employees/operations?

– Brad Nadell: I became good friends with some of the drivers

that delivered the blanks. Most of these

friendships still exist to this day. As

far as operations go, I wasn’t super involved.

The main interaction regarding operations was for Clark to understand

our business model and for us to understand how things operate down there. From that mutual understanding we together

with Clark developed the method of keeping a consistent stock of blanks at Foam

E-Z amid the high the demand that was put on us.

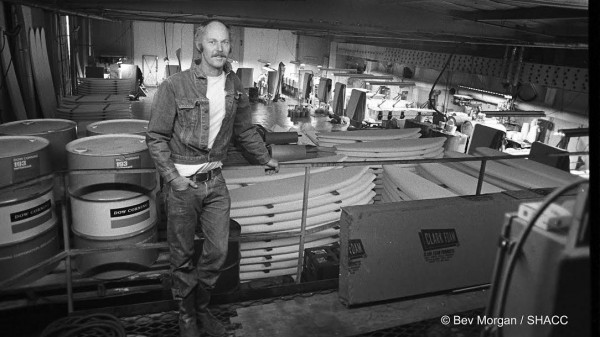

|

| Brad Nadell surrounded by Clark blanks in the Foam E-Z warehouse |

other competition with other blank manufacturers?

– Craig Larsen: Walker

Foam and occasionally some various Australian blanks. Really mainly the shaping

machines. He used to say that KKL was Al Merrick’s blank supplier, not Clark

Foam. To be honest, not a lot of

competition. Back in the 60’s and 70’s there was a lot of competition, but most

the companies crashed and burned over credit wars. I’ve heard all the crazy stories of all the

evil things that we did at Clark Foam, but while I worked at Clark Foam those

stories were BS. There was a time in the late 90’s that we were definitely

oversold and we had to put the market on allocation and make some hard

decisions. Pretty stressful time. With that said, I would have hated to compete

against Clark Foam, it was such an efficient machine and Gordon really

understood how to add value beyond making a blank. There were a lot of value

adds that customers really didn’t think about until after Clark Foam shut down.

He made things very convenient for customers. Beyond the 70+ different blanks

in 5+ different weights with an extensive custom rocker program, we had the

keys to just about every shop in California so we could deliver blanks without

customers being around. Also the credit

side of things was huge, we would work with just about anybody as long as you

were actually a builder. Because we

didn’t have a lot of competition, our customers were a lot more accountable to

paying Clark Foam in a timely manner. I’m sure after Clark Foam shut down, the

credit side of things got ugly for all the new blank builders.

– Matt Barker: Off and on there was competition- but our level

of service, broad product offerings, and deep relationship with our customers

were a very effective entry barrier for others just showing up on the

scene. Additional our highly efficient

systems and processes allowed us to keep prices very competitive. We basically kept competition to a minimum by

doing our job really well.

– Tami Mays: I wasn’t aware of any.

– Matt Stevens: No, not really. There was always something

getting hyped up, some new blanks or “new” board building technology, but it

was usually just hype or a recycling of something that had been tried before.

As I recall, the Australian and Brazilian foam markets were well served by

themselves. I’m not sure if there was ever the manufacturing capacity to

support a market outside of their own anyway. Whether it was good foam or junk foam

was always up for debate and depended who you talked to, but it did show up

here or there sometimes. On a global basis, we shipped containers regularly to

Europe, Japan, South America, and on occasion to other places we as surfers

want to be (Central America, South Pacific, etc.). Never can I remember one

shipping to Australia.

We probably created competition elsewhere by shipping

abroad, but only once in a while would a supply of Aussie Burford or Bennett

blanks would show up somewhere and a container would get sprinkled around a

local market. Same thing with the occasional domestic Walker Foam delivery

you’d run across in someone’s factory. We didn’t see or know of much else with

any regularity. New stuff would usually end up as shaping machine back room

inventory when hand shapers got tired of trying to work too hard for a quality

shape. Most shapers were all-in, but there were definitely those who were a

none-at-all thing with Clark Foam, not much middle ground. So, yes, there was

always some other foam to be found here and there, but nothing consistently or

in steady supply. There was always someone pushing something new, ‘whiter or

lighter’, but with very rare exception did that mean it was even close, let

alone better. I’m rambling here, but I

could go on a bit on this topic…some fun stories of game changing alternatives

to the PU blank, long standing feuds, egos, and myths of strong armed business

tactics!

competition ever, at that time, from other blank companies who wanted you to

sell their blanks?

– Brad Nadell: Before December 2005 (Blank Monday) there was really

no competition. Walker Foam was out

there but I didn’t have the need to carry their blanks as Clark was servicing

our needs extremely well. That’s one of

the strategies they used to insulate themselves against the competition. From time to time Walker would hit us up to

sell their blanks but nothing materialized until after Clark Foam was gone.

visit their factory, what was it like?

– Brad Nadell: I visited the factory about once every other

month. Sometimes it was to check out

operations other times it was simply to grab lunch with one of the guys. The factory was really amazing to me. Never before had a seen a factory where

something was manufactured from start to finish. Clark had everything in raw material form

from the chemicals to the wood. He had

his own wood shop, tool repair shop, foam pouring shop, stringer cutting shop,

gluing room, staging area, shipping area, and so on. It was like a full blown city on a small plot

of land set in Laguna Niguel.

operation at your time there?

– Tami Mays: I’m not sure the exact number of how many blanks we

shipped, but we did have over a hundred employees at the factory.

– Matt Stevens: 100 employees. The glue shop could finish

slightly more than the foam shop could produce on a daily basis. There was a

new batch of a couple thousand blanks being blown, glued, and shipped

approximately every two days. Pretty sure it was approximately 960 vs 980 per

day, but could be wrong. In each batch, we’d have a minimum of one, oftentimes

two, shipping containers and local orders for delivery. I don’t recall how many

blanks in inventory at the factory we could hold at capacity, but under periods

of high demand, the inventory of uncut raw blanks could be depleted pretty

quickly as the short term supply answer was to throttle up the glue shop and

get blank orders out the door. The foam shop had more of a capped production

capacity. The skilled foam shop workers were the longest tenured guys, and

could run 24/7. The glue shop guys could get trained up and cross trained

quickly at any number of positions and were able to run 5am to 10PM for

everyday stretches with some creative scheduling.

The constant balance of

manpower and material resources was something else! Gordon introduced the

‘cubeta’ (Spanish for bucket) which was an employee profit sharing program

based on a complex ratio of maximizing production while minimizing

manufacturing resources. I never fully broke down the complexities behind it,

but we all knew when we were working flat out for periods and it was kind of

fun to watch the money in the cubeta grow. It was a pretty unifying tool for

the troops, encouraging all 100 employees to be on the same page with production

goals. We also had medical benefits and vacation accrual too. It was a pretty

good size operation and it was fun to be a part of such a unique small to

medium size business.

– Matt Barker: We

strived to scale our production output to sufficiently service all our

customer’s needs in a timely manner. We

had a pretty good track record of consistently taking care of our customers.

– Craig Larsen: Probably

110 employees. During the late 90’s we had the foam shop going 7 days a week 24

hours a day with very little overtime. This was a huge feat.

How did you first

How did you firstfind out Clark’s factory doors were closing for good, what was your reaction?

– Matt Stevens: While everyone received the

public facing notice of closure at the same time, there were some troubling

signs coming up to that day. Matthew Barker had already moved on to work for

Hurley (Matthew is an awesomely talented guy, and his career change timing was

impeccable). Kim Thress had left Clark Foam a couple months prior. (Most

everyone in-the-know of surfboard manufacturing knows Kim, knows of Kim, or

should know that Kim has put more heart and soul into supporting the board building

industry than almost anyone alive). Reed had recently retired after

several decades of working for Gordon. And, even ‘Chuey’ had

retired and left for Mexico. A full century of blank building knowledge and

expertise right there had already left the building! The place was still in

very capable hands though, including Gordon and Nikki’s very bright and

recently graduated daughter Sarah. Gordon was under some real pressures, maybe

not what the famous letter of closure to customers indicated, but not far from

the truth either.

Anyway, fast forwarding to the

morning the whole thing ended, Gordon and Nikki showed up to the office mid-morning

and for some reason I distinctly remember being on the phone with Pat Rawson

and thinking to myself, this ain’t good. They walked in both visibly upset and

called a meeting back in the maintenance room. I remember the walk back there

thinking we would hear something awful like a malignant cancer diagnosis. From

memory, it was me, Joel, Patty, Jeff Holtby, Sergio and Luis.

Among other things, we were basically told that we just poured our last blank

and we would be closing for good. The explanation we got didn’t allow for many

questions.

My reaction? I was stunned

obviously. I had a wife and a brand new mortgage and no advanced notice. There

were a lot of people, a huge community of board builders and Clark employees

alike, worrying about providing for their own families too among other stresses

when people find out suddenly that they have to stop making a living for a

while. For a while, I carried around some guilt for letting down so many board

builders that became good friends. Gordon gave everyone the option of staying

on for a few weeks while the factory was gutted and either destroyed or

auctioned off. Pretty stressful time, and I wasn’t very fond of being on the

front lines of damage control with people looking for answers. I came to the

conclusion that I, like our customers and every other employee, was just a

casualty of a bad situation and so I decided to cut out after just a couple of

days. It was a dark time, but I hope that everyone came out of the adversity a

little better than they were before.

– Craig Larsen: I had moved to Utah by then. My phone started

ringing off the hook. Even had a couple people show up at my house in Utah

asking questions about key Clark personnel.

– Matt Barker: I received a phone call from a Clark Foam

associate at the very moment it happened (I was actually standing in a tee

shirt warehouse working on process improvements for Hurley). My reaction was

three fold; concern for my longtime shaper friends (losing a vital business

partner), and for the many dedicated employees at Clark Foam (losing their

ability to provide for their families), and for Gordon having to fold up his

life’s work. It was a very tough day for

everyone. But like most things, it all

ends up working out over time.

– Tami Mays: I had left Clark

Foam a few years before and, just like everyone else, was shocked when I heard

the news of Gordon’s decision. I heard from a friend and I suppose I was

relieved that I had moved on before it all went down.

How much forewarning did you have regarding

Clark’s closure?

– Brad Nadell: ZERO… I

was working at my home office when “The Fax” came through. My only

employee at the time called me and said something weird was going on. As faxes go… this one especially was

extremely hard to read as it had a white stripe going through it

vertically. Even though the fax was

difficult to read we got the picture real quick.

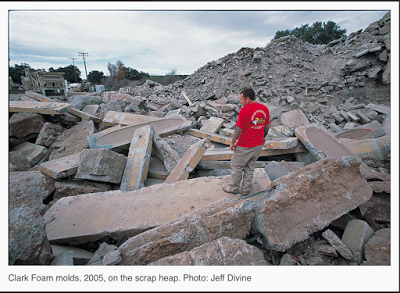

|

| Destroyed Clark Molds |

certain extent, Clark Foam was the surfboard-building life-blood for quite a

while. Do you think there was a feeling of betrayal or unfairness at all after

the doors were locked and the molds were destroyed?

– Matt Stevens: A feeling of betrayal is a

good way of characterizing what a lot of people felt. I understand some of the

reasoning behind it, but it probably could have been executed a little

differently. Everyone has an opinion on this, how they would have done it. But

in the end, sound reason and good judgment don’t always drive the outcome.

Tami Mays: I’m sure that Clark Foam’s customers were left feeling

cut off at the knees when Gordon decided to close. It’s unfortunate that it

created such a panic and that it ended for many with a sense of betrayal. I’m

hoping as the years have gone by that other manufacturers have filled the hole

in the blank supply that Clark Foam left.

Matt Barker: I

cannot speak on behalf of Clark or Clark Foam- but here are my two cents. Of

course there are some people that would like betrayal to be the narrative- but

that is mainly coming from those not close to the events and communication that

unfolded.

For the record, every shaper’s

plugs (that new molds that subsequent molds are built from) where returned to

the shaper/designer by Clark Foam for use with their future blank supplier (and

to benefit the broader industry). The

molds themselves were destroyed as well as some unique equipment because this

equipment was designed and built on site at Clark Foam, and would have carried

a tremendous safety liability in the hands of others.

Additionally Clark Foam worked

closely with its long-term customers to get them what they needed (Blanks) from

the remaining inventory (which was very extensive). I will leave the “why it happened” to Clark’s

official announcement to his customers at the time.

– Craig Larsen: Gordon

understood the history of the surfboard market better than anyone. He is one of

the smartest people I’ve ever met. Every time I ever second-guessed Gordon, 6

months or a year later I would be proven wrong. Every time. So I’m not going to

second guess him on how he shut Clark Foam down. He was always concerned about

what was best for the surfboard builder and the overall market big picture. My

theory (although probably wrong) is he shut the plant down suddenly, destroying

the molds, because he knew this was fastest and best way for the market right

itself. What would the affect been to

the market if he handled the closing differently? Better? Maybe for some, but

maybe not for a lot of builders. Hard to say, but I’m not going to second guess

him.

was it like for you, as a distributor, in the days and weeks following their

closure?

– Brad Nadell: Extremely

scary! Basically didn’t know what the

future would hold. It was like there was

not going to be any more milk available or toilet paper or really anything that

we all depend on to survive. I had to

pull my roll up door down and lock the doors.

The phone was ringing off the hook and I swear we had like 200 messages

in one day. I didn’t open the shop again

for four or five days. Needed to sort

out the situation and try to make the best decision for all involved.

other blank manufacturers step up to fill the void immediately, or was there a

vacuum of blank availability for a while?

– Brad Nadell: Well

luckily for us Clark offered us a large number of their back stocked

blanks. Which we allocated this last

gasp of Clark Foam Blanks to our customers in a very methodical way, as to try

to take care of the shapers that took care of us over the previous twelve

years.

After these Clark Blanks were

gone (about two weeks), we started trying to figure out our next step. I was meeting with blank manufacturers from

all around the world. They all flew over

here after Clark closed and were trying to suck up the business. Some of my competitors decided to bring in

containers of blanks from around the world but we didn’t. I reached out directly to Walker Foam and

began a relationship with them. Luckily

for me Gary Linden was doing their customer relations at that time and we had a

previous relationship as we had provided him blanks and tools from time to

time.

The other key ingredient to

this relationship was our proximity to Walker Foams factory. Huge props to Walker Foam for supplying us blanks

during a tumultuous time and helping us bridge the gap from Clark Foam to where

we are today. Unfortunately for Walker

Foam, the over expansion to meet the demands of the market ultimately was their

demise.

Clark’s final days. Do you have a plan to ever shape those or will you hold

onto them as a collector?

– Brad Nadell: I gave a few of the blank to some of our employees to

shape up. We need to check in and see

what they thought. I am keeping one or

two in my rafters as a little memory of the Clark Days.

|

| The Foam E-Z Clark Blank Collection |

did you move onto after working at Clark Foam?

– Craig Larsen: Gordon

always used to tell us that Clark Foam was a great place to learn, but if you

wanted to make a decent living you better go work somewhere else. It was the

surf industry for god’s sake. So in 2000 I decided to take his advice and try

to make a better living. He was right about learning a lot. I use knowledge I

learned at Clark Foam every day in my job now.

I left Clark Foam in 2000,

first to Revchem doing technical sales. In 2002 I moved to Park City Utah to do

technical sales for Composites One covering Utah and Colorado. I have customers

that make everything from bowling balls to rocket ships, snowboards to rocket launchers.

I miss the ocean, but not all the hordes of surfers. Surfing sure got popular in the 90’s.

Matt Barker: I had previously left Clark Foam for Hurley about 4

months prior to its closing. I’ve

been with Hurley for nearly 11 years. While at Hurley I have managed customer service

& compliance, distribution operations, directed operations in our printables

department, launched our sustainable business & innovation efforts (as well

as helped shape and launch Hurley’s Born

From Water– H20 initiative), led our Apparel Production Team, worked on

wetsuit performance development, special surf projects, and currently our

product creation operation. Each of these roles/contribution to Hurley were

direct results of the deep experiences learned at Clark Foam. Hurley is a

fantastic place to work (and was started by a shaper Bob Hurley).

The reason for leaving Clark

Foam was the feeling that Clark Foam, like industries, were no longer going to be viably

operating in much of Southern California due to the ever tightening regulatory

requirements and unfriendly business environment. So I realized that my family’s future

provision needed a better long-term solution. I then found a new career away

from plastics manufacturing. It was the

hardest decision I’ve ever made. I loved my work at Clark Foam, and I

especially loved (and now miss) all of the great lifelong surfboard building

friends locally and around the world, as well as my Clark Foam Family. The good news is virtually all of the intellectual

strengths of Clark Foam came back together in the form of U.S. Blanks.

Tami Mays: The last few years I

worked at Clark Foam I was taking classes to obtain my teaching credential. I

quit when I was ready to student teach. I’ve now been teaching for 13 years.

– Matt Stevens: Baja for a while, Ha! As life goes, my next

chapters have been better for me and my family. I had a friend who encouraged

me to get out of my comfort zone and get my act together a little bit for a

more corpo gig. Maybe a little bit more money, but not nearly as fun as the

good old days.

has the industry changed since Clark closed its doors, from your perspective as

a business owner? Is there a greater diversity or access to blanks?

– Brad Nadell: It is a

completely different world now. Many

different options as far as EPS and other foam manufacturers go. The biggest difference for us is the fact

that pretty almost all professional shapers use a shaping machine. These cutting houses usually stock the blanks

now and therefore cutting us out of the mix.

At one time you either had to get your blanks from Clark Foam directly,

or from us or one of the other local blank suppliers. We now service the home-builder more so than

the pro-shaper, but still have our loyal clientele from the old days. Whenever a pro-shaper needs a blank for a

hand shape or any tools they still either stop by or call the shop. A small number of pro-shapers who do not get

their blanks cut buy their blanks from us

have you noticed in the board building world in the last 12 years?

– Brad Nadell: The biggest one is a big shift away

from hand shaping. Also more unique

shapes are being tested and surfed on a regular basis. Definitely people are building boards on the

thicker, wider, rounder easier-to-catch-waves spectrum. Since surfing is more mainstream now

entry-level boards cover a broad range.

Fishes, Mini-Simmons, stubbies… basically anything with volume seems to

be hip.

favorite memory from working in the Clark factory or with Gordon Clark?

– Tami Mays: With such a small office staff, we really did feel

like an extended family most of the time. I will always remember celebrating

co-workers’ birthdays with cake! The relaxed and casual environment was

comfortable and friendly, but it really was all business with many routines and

procedures in place to make it run smoothly. Gordon was a big proponent of

always learning more. He would go out of his way to help people acquire the

skills needed to keep our factory on track.

– Matt Stevens: On the factory side, it was the scream of

the stringer router, the faint smell of styrene, the pumping mexi music, and

the good people I worked with.

the factory, I had the privilege of peeking in on literally hundreds of shaping

rooms and artists, soaking in as much as I could. I love surfboards and I love

interesting people, and a decade at Clark Foam provided plenty of both. Can you

imagine the thrill of Terry Martin saying, “Here, I’ll show you how…it’s just a

dance”? Walking into a pre-dawn Natural Curves factory, fog and reggae so thick

you could cut it with a knife, to meet Steve Coletta? Rich Harbour talking

story (ask him about seeking legal advice from Gordon back in the day)… These

guys were/are just legends! Wayne Rich shaping sessions… to a Rick Hammon quick

tutorial on turning a rail… to stints in Wahiawa… the cast of characters and

free shaping tips! Leading the herd was Gordon Clark, probably the smartest man

I’ve ever met. He was good to me, and I think many board builders would agree

he was good to them as well.

– Craig Larsen: Probably

my favorite memory of Gordon was while I was still a fairly new employee I was

in the same office doing work that Gordon and the fire department and county

fire officials were in having a meeting. The meeting started to get heated and

I remember Gordon looking at one of the officials and telling him “If this was

Texas and you tried to do this to a business you’d be hanging from that tree

outside this building.” Scared the shit

out of me.

– Matt Barker: My

favorite memory as a surfer was being asked by Gordon to “stay on the clock and

take Gerry Lopez surfing”. My first role at Clark Foam (when I was 21) was

helping Gordon build a new Foam Machine (I helped with wiring and

plumbing). One day the wind was

offshore, and there was a 6’ south swell and I was working on the Foam

Machine. Gordon called me from his home

and said, “Are you busy?”

I said, “Of course.”

Then he said, “I

need you to do something- don’t punch out, get your surfboard, drive to my

house and take Lopez surfing.” I grabbed Gerry and we went to Salt Creek. He had never ridden a thruster so we traded

boards (mine was a 5’10” Max McDonald Thruster made with experimental

“Ultralight” foam). So we traded boards

before paddling out. One of the older

guys at Creek that always treated me shitty like a grom and said to me, “Hey

you see who that is,” motioning towards Lopez.

I said, “Yeah I know. He’s here with me and

he’s riding my board.”

The guy yells “Bullshit!”

I go, “No really,” and lift

Gerry’s board that I was riding up out of the water. The look on his face was priceless. That is one of the countless special memories

while being a part of Clark Foam.

So yes, I once got paid to take Gerry Lopez surfing… who can say

that?

One comment on “The End of Everything: Looking back on the Clark Foam Legacy 12 Years Later”

I worked for Gordon Clark and the gang for 12-1/2 years – from 1983 to 1996. During my time there, I worked in the maintenance department, ran the Woodmill, and moved into the office to take over inventory scheduling for all of our warehouses. I developed a charting system that assisted us in making sure the right stock was in the right place – the Hawaii and Florida warehouses – at the right time. During my time running the woodmill, a drastic shortage of redwood came into play. I was tasked with coming up with an alternative; a hardwood that was stable, easy to shape, AND the right color. After working with the supplier for a long time, we finally settled on Western Red Cedar – it had the strength and stability necessary, and the color was pretty much right on. It also shaped easily. So, suffice it to say that Gordon Clark was always open to input and contributions from his employees. It's funny – as to Gordon notifying the factory he was shutting down his operation via FAX … well, imagine that. After 12-1/2 years, I was actually TERMINATED by fax. The letter brought me to tears, because it was devastating to me. I'd spent a whole lot of my life there, and I worked hard and learned a lot. When he let me go, I knew why; I was not a "Yes Man" and I argued my points. I also had nowhere to climb any higher than I already was in the company, due to long-term employees in positions above me. So, he did me a HUGE favor by sending me off to make my future somewhere else. I harbor no grudges against him – working at Clark Foam remains a great memory for me, and I feel I was a part of surfing history. I may not be well-known, but some of what I did made many, many surfers' lives more fulfilling – if only because they got their board when they wanted it – and with the right wood. Thanks, Gordon! You old bastard, you. 😉

Comments are closed.